HVAC Equipment

Capabilities:

Air Handling Units (DX and Chilled Water)

Fan Coil Units (DX and Chilled Water)

Condensing Units

Packaged Air Conditioning Units

Packaged Terminal Air Conditioning (PTAC) Units

Ductless Split Systems

Variable Refrigerant Systems

Air Cooled Chillers

Water Cooled Chillers

Evaporative Coolers

Supply and Exhaust Fans

VAV Terminal Boxes

Fan Powered Terminal Boxes (Parallel and Series)

Computer Room Air Conditioning (CRAC) Units

Chemical Filtering Systems

HEPA Filtering Systems

Chilled Water Pumps

Hot Water pumps

Hydronic Systems Accessories

Energy Recovery Systems

Run-Around Coils

Air Control Venturi Valves for Laboratories

Laboratory Fume Hoods, CAV and VAV

Laboratory High-Plume Exhaust Fans

Services:

Provides supporting services to Clients in Oil and Gas, Chemical, Petrochemical, and Pharmaceutical facilities, Hospitals, Laboratories, Clean Rooms, Emergency and Urgent Care, Institutional and Commercial in the following areas:

Perform HVAC Load Calculations

Design HVAC Systems for precise temperature, humidity, and pressurization control

Perform System Selection Based on application

Equipment sizing and selection

Design air distribution systems

Design Chilled Water and Hot Water Distribution Systems

Design Chilled Water and Hot Water Plants

Provide calculations and design pressurization Systems for Laboratories, Hospitals, Pharmaceutical facilities, etc.

Design Clean Rooms

Provide Air Flow/Control Diagrams and Sequence of Operations for Equipment and Systems

Perform Building Energy Audits and suggest Energy Saving Measures for building performance improvement.

Heat Transfer

Capabilities:

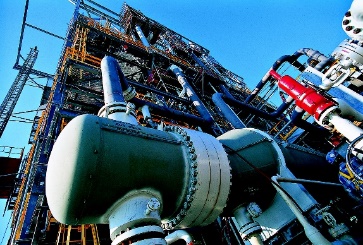

Provides supporting services to Clients for all areas of design, fabrication and construction.

Expert assistance in the following areas:

Shell and Tube Heat Exchangers (ASME / TEMA / API 660)

Air Cooled Heat Exchangers / Air Cooled Condensers (API 661)

Double Pipe / Hairpin Heat Exchangers

Plate Style Exchangers (API 662) – Spiral Plate, Plate and Frame, Welded Plate, Plate and Shell

Brazed Heat Exchangers

Printed Circuit Exchangers

Ground Flares, Enclosed Flares, Elevated Flares and Burn Pits

Elevated Flare Riser Sizing and Tip Selection (API 521 / API 537)

Incinerator (Reaction Furnaces) and Waste Heat Boilers (Sulfur Condensers)

Heat Loss Calculations (Piping Systems, Thermal Issues in Plant Layout)

Tank Heaters (external and internal)

Packaged Units

Skid Units (Fuel Gas Treating, Ammonia, Filtration, Flow Metering)

Water Treatment

Attemperators

Boilers

Burners (API 560 / NFPA)

Condensers

Cooling Towers

Refrigeration Style Coolers

Deaerators and Degasifiers

Dehydration and Dryers

Steam Drums

Stacks

Scrubbers

Preheaters

Flares

Heat Exchangers – forced-draft air cooled, cooler w/ recirculation, hairpin, spiral plate, stacked, welded plate, printed circuit

API 560 & 530, ASME B31.3, NFPA 85/86

NOX and CO – reducing technologies

Hot Oil Heater System

Incinerator / Thermal Oxidizer Package

Turnkey Packaged / Field -Erected Boilers

Flare Tips, Molecular Seal & Stack

Cooling Towers & Wet Surface Air Coolers

PAS Units

Packinox Heat Exchangers

Services:

Assist in preliminary design estimates

Feasibility Studies

Emission Studies

Dispersion Analysis

Thermal ratings / sizing and hydraulic of exchangers

Equipment Cost Estimates

Code calculation on shell-and-tube exchangers

Assist in developing project schedules

Provide or assist in developing equipment design criteria

Provide design calculations (HTRI, COMPRESS, PV Elite, EDR) for: heat exchangers, select applicable heat transfer rate and shell and tube arrangements

Provide setting plans for heat exchangers incorporating all dimensional information and structural loads

For fired heater and furnaces, provide conceptual design complete with selection of auxiliaries such as combustion air preheaters, selective catalytic reduction units and forced-draft and induced-draft fans.

Develop and/or review equipment specification and standards

Data sheet preparation

Develop Inspection Test Plans (ITP)

Prepare or review equipment inquiry requisitions

Prepare or review Technical Bid Analysis

Review supplier fabrication drawings

Provide project support for equipment installation and startup

Perform pinch analysis, economic feasibility study and heat loss analysis

Thermal Radiation & Noise from Flares

Witness testing

Fired heaters rating check and optimization vertical cylindrical versus box or horizontal cabin)

Heater rating check & draft calculation, optimization, retrofit and combustion study

Steady-state & transient heat transfer analysis using FEA

Fired heaters rating check and optimization

Cooling Towers

Packaged and Stick Built

Fired Heaters

Cabin Heater

S&T Heat Exchanger

Air Cooled HX

Boilers